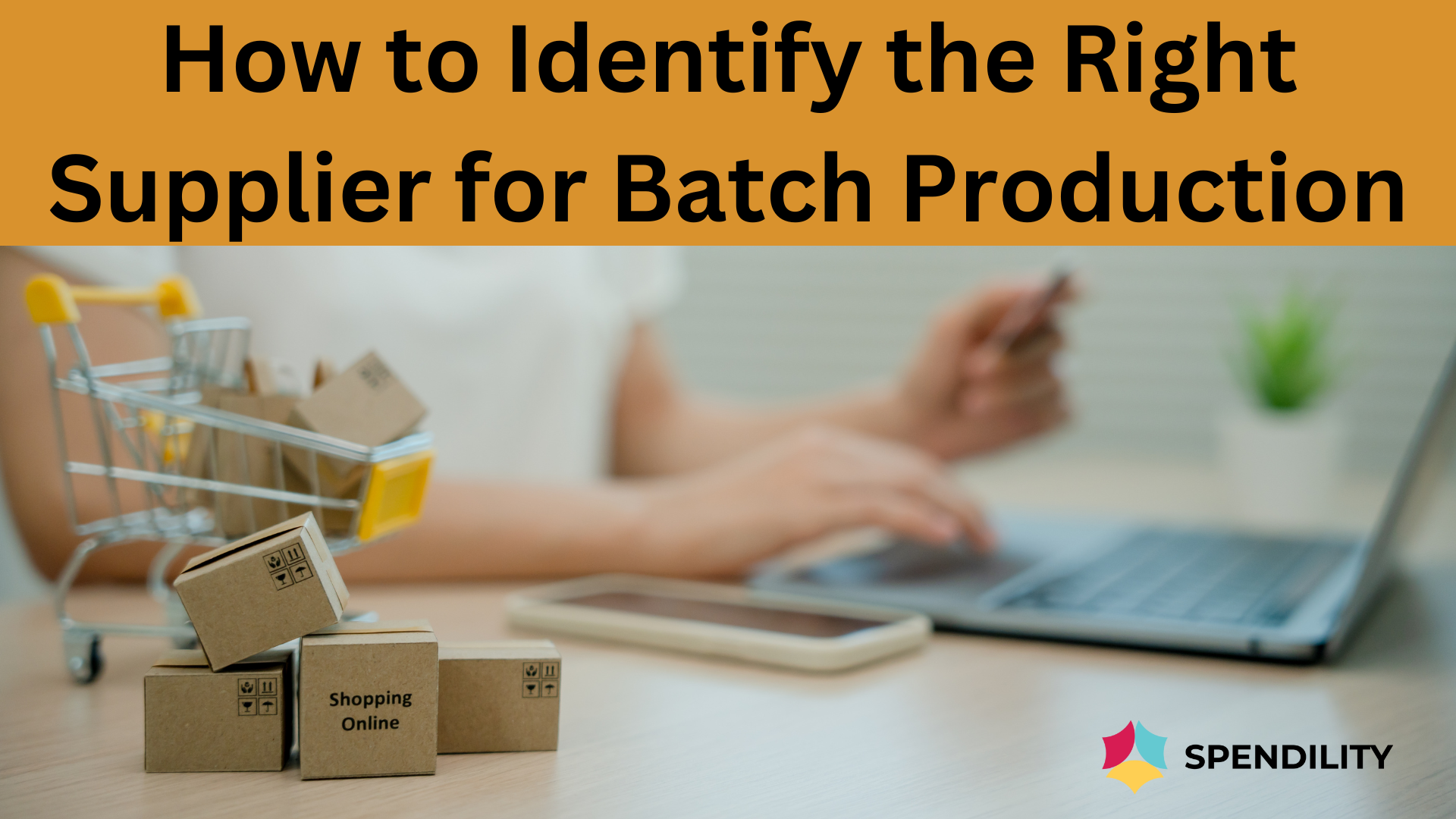

Finding the right supplier for batch production is crucial for the success of any manufacturing business. The right supplier can ensure quality, timely delivery, and cost-effectiveness, all of which are essential for maintaining a competitive edge. This article will guide you through the key steps and considerations in identifying the right supplier for batch production, helping you make an informed decision that aligns with your business goals.

1. Understand Your Production Needs

Define Your Requirements

Start by clearly defining your production requirements. This includes the type and quantity of products you need, the quality standards you expect, and the production timeline. Having a detailed specification of your needs will help you communicate effectively with potential suppliers and evaluate their capabilities accurately.

Determine Your Budget

Establish a budget for your batch production. Consider all costs, including material, labor, shipping, and any additional expenses. Knowing your budget constraints will help you narrow down your options and find a supplier that offers the best value for money.

2. Research Potential Suppliers

Industry Directories and Trade Shows

Use industry directories and attend trade shows to find potential suppliers. These platforms offer a wealth of information about suppliers, including their capabilities, certifications, and past performance. Networking with industry peers can also provide valuable insights and recommendations.

Online Marketplaces

Online marketplaces such as Perfaktry, Alibaba, ThomasNet, and Global Sources are excellent resources for finding suppliers. These platforms allow you to search for suppliers based on specific criteria and read reviews from other businesses that have worked with them.

Supplier Audits

Conduct supplier audits to verify the authenticity and capabilities of potential suppliers. This can include visiting their facilities, reviewing their production processes, and assessing their quality control measures. An on-site audit can provide a deeper understanding of a supplier’s operations and reliability.

3. Evaluate Supplier Capabilities

Production Capacity

Ensure the supplier has the production capacity to meet your batch production needs. Ask about their current workload, lead times, and ability to scale production if necessary. A supplier with sufficient capacity will be able to handle your order efficiently and accommodate any changes in demand.

Quality Control

Assess the supplier’s quality control processes. This includes their methods for inspecting raw materials, monitoring production, and conducting final product inspections. A supplier with robust quality control measures can consistently deliver products that meet your specifications.

Certifications and Compliance

Check if the supplier holds relevant certifications and complies with industry standards and regulations. Certifications such as ISO 9001 indicate a commitment to quality management, while compliance with environmental and labor laws ensures ethical production practices.

4. Analyze Cost and Terms

Price Comparisons

Compare prices from multiple suppliers to ensure you are getting a competitive rate. Be cautious of prices that seem too good to be true, as they may indicate lower quality or hidden costs. A thorough cost analysis should include material costs, labor rates, and any additional fees.

Payment Terms

Review the payment terms offered by each supplier. Favorable terms, such as flexible payment schedules or discounts for early payments, can improve your cash flow and financial stability. Ensure that the payment terms align with your financial capabilities and business operations.

Delivery and Logistics

Evaluate the supplier’s delivery capabilities and logistics network. Reliable delivery schedules and efficient logistics are essential for maintaining your production timelines and minimizing downtime. Consider the supplier’s location, shipping options, and their ability to handle any customs or regulatory requirements.

5. Build Strong Relationships

Communication

Effective communication is key to a successful supplier relationship. Choose a supplier who is responsive, transparent, and proactive in addressing any concerns. Regular updates and open lines of communication can help prevent misunderstandings and ensure smooth operations.

Long-term Partnership

Aim to build a long-term partnership with your supplier. A stable relationship can lead to better pricing, priority treatment, and improved collaboration on product development. Investing in a strong supplier relationship can yield significant long-term benefits for your business.

Continuous Improvement

Encourage continuous improvement in your supplier’s processes. Regularly review their performance and provide constructive feedback. Collaborative efforts to enhance efficiency, quality, and innovation can lead to mutual growth and success.

Conclusion

Identifying the right supplier for batch production involves a thorough understanding of your production needs, extensive research, and careful evaluation of potential suppliers. By considering factors such as production capacity, quality control, cost, and communication, you can make an informed decision that supports your business goals. Building a strong, long-term relationship with your supplier will further ensure the success and sustainability of your batch production efforts. Follow these guidelines to find a supplier that meets your needs and helps drive your business forward.

Contact Spendility today for a free consultation and discover how we can transform your business.